Tube & Grid Magnets

Tube and Grid Magnets are one of the most extensively used magnetic separators produced by Bunting. Tube Magnets (Magnetic Rods and Cartridge Magnets) are used individually or in multi-rows to remove problematic ferrous metal from processed materials, prevent damage to processing equipment, and protect product quality. The range of strengths includes Ceramic Ferrite for the separation of larger tramp ferrous metals and high-strength Rare Earth Neodymium for the capture of smaller ferrous metals and abraded stainless steel. Tube Magnets are used extensively in the food, plastics, ceramics, and processing sectors.

Description

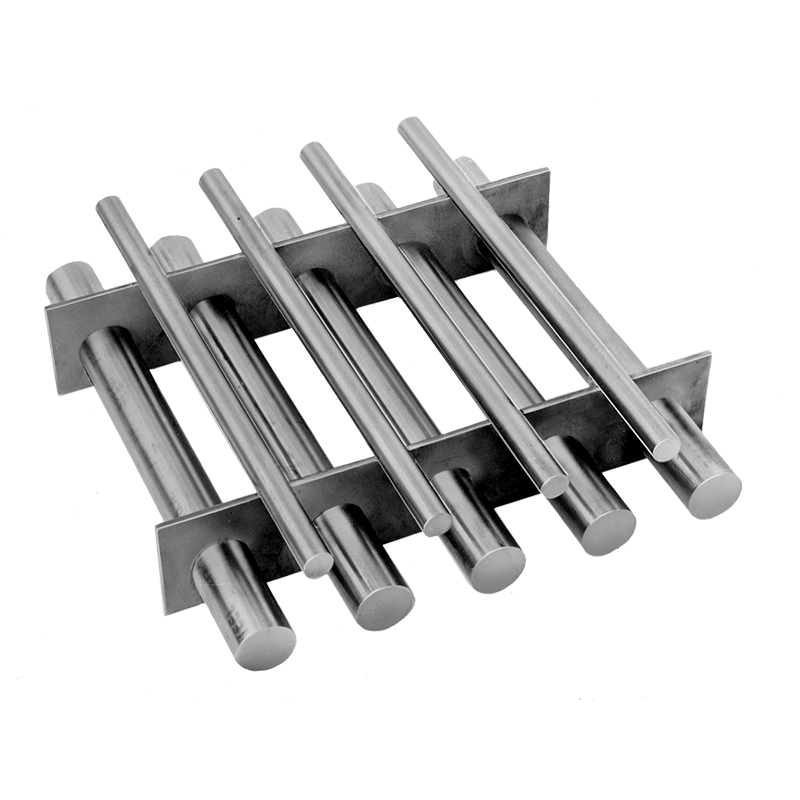

Tube Magnets, also known as magnetic rods, grid magnets, or cartridge magnets, are engineered to achieve the optimum balance between magnetic throw and holding force, they are designed for mounting individually or in multi-row grid arrays; providing a versatile product for both dry and wet gravity-free-fall magnetic separation applications.

The range includes standard-strength Ceramic Ferrite and high-strength Rare Earth Neodymium.

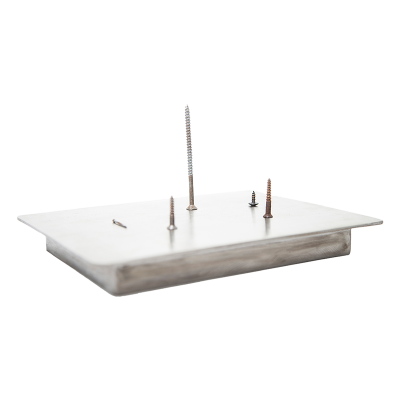

Tube Magnets are available in both standard and heavy-duty models and are constructed of durable 304 stainless steel tubing, with 316 available for specific applications. The ends are fully welded with the option of threaded holes, threaded rods, or plain water-tight sealed end plugs. The standard diameter of a Tube Magnet is 25.4mm (1”) with standard lengths from 100mm to 600mm.

Tube Magnets are commonly constructed into a Grid for installation in hoppers, pits, chutes, housings, and bins. Grid Magnets, otherwise known as Grate Magnets, are available in a wide range of dimensions, both circular or square, to meet application requirements. Additionally, Grid magnets are available in food and sanitary grades to meet specific industry standards.

Tube and Grid Magnets feature in Drawer Filter Magnets, where they are mounted within a sealed housing for easy installation into a process line.

- Technical product information: Drawer Filter Magnets

A range of Tube Magnets and Grid Magnets are available for online purchase on the Bunting-eMagnets website:

Related Blogs about Tube Magnets and Grid Magnets

Operation of Tube and Grid Magnets

In operation, a liquid or dry product is passed over the surface of the Tube Magnet, where magnetically susceptible particles are attracted and held by the magnetic field. Periodically, in accordance with the degree of ferrous metal contamination, the Tube or Grid Magnets are manually removed for cleaning.

Tube Magnets and Grid Magnets Models

The range of Tube and Grid magnets includes:

- Standard-strength Ceramic Ferrite – ideal for separating large tramp ferrous metal such as nuts, bolts, screws, etc;

- High-strength Rare Earth Neodymium – intense magnetic power for capturing fine iron and abraded stainless steel in applications with special magnet specifications for applications where the temperature exceeds 80°C:

- 11,200 Gauss;

- 10,000 Gauss;

- 4,000-5,000 Gauss;

- 2,500-2,900 Gauss;

- High-strength Rare Earth Samarium Cobalt for very high-temperature applications above 180°C;

Applications of Tube and Grid Magnets

Tube and Grid Magnets are extremely versatile and are used in a wide range of applications including:

- Food processing plants, especially for lumpy foodstuffs:

- Soups;

- Baby food;

- Sauces;

- Pet food;

- Grain;

- Plastic manufacturing operations;

- Recycling;

- Ceramics

- Raw materials;

- Glazes;

- Slips;

- General powder and bulk handling;