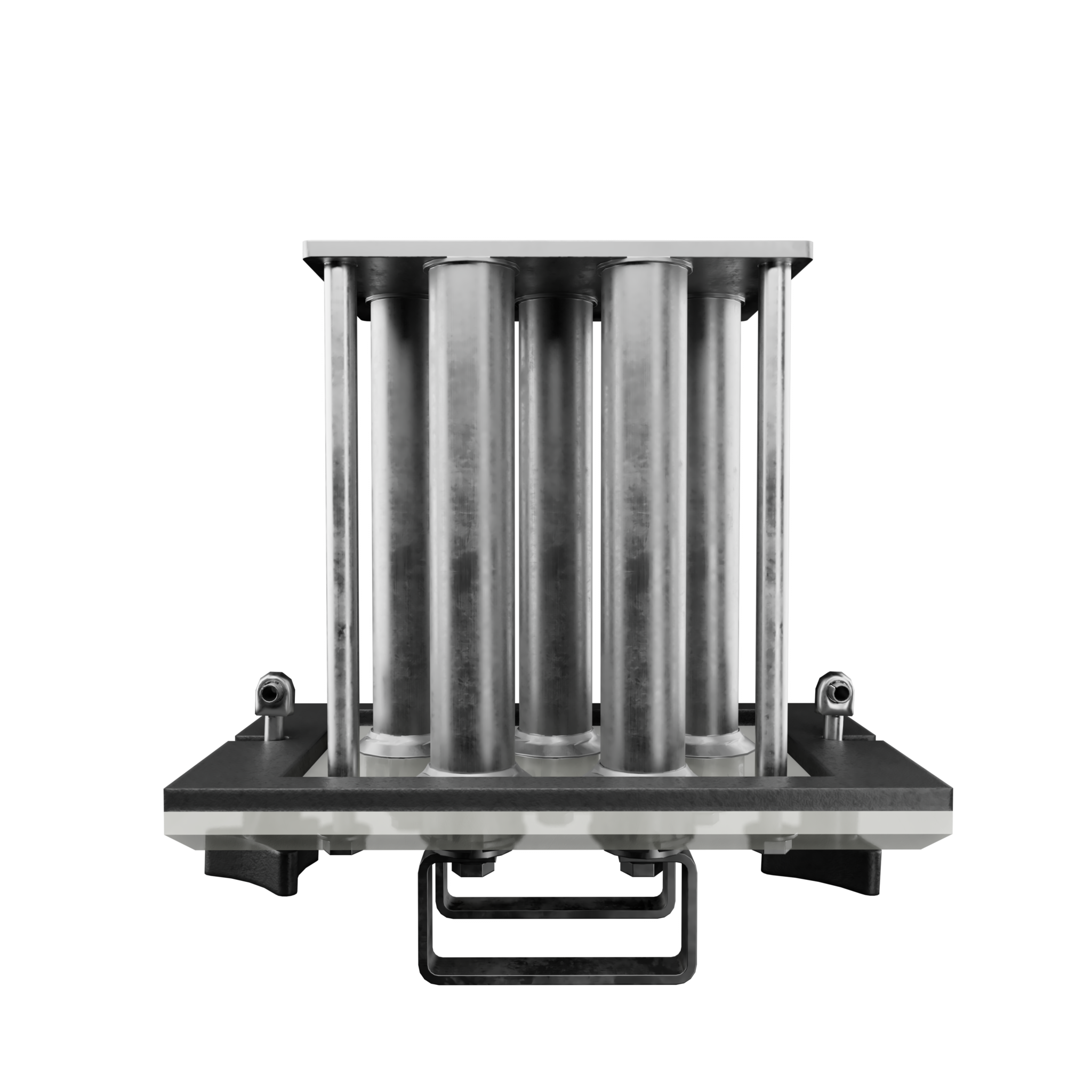

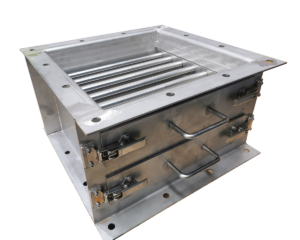

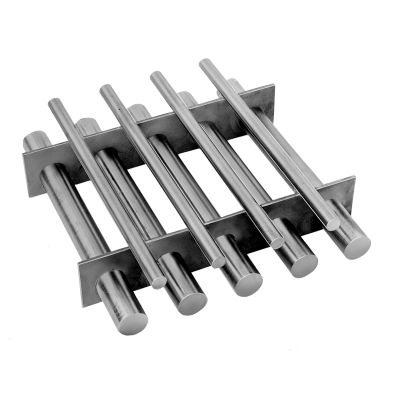

Drawer Filter Magnets

Drawer Filter Magnets are equipped with powerful magnetic cartridges to extract ferrous particles in gravity flow or free-fall applications and are able to withstand temperatures up to 80°C without compromising magnetic efficiency.

- High-efficient Rare Earth Neodymium magnets

- Withstand temperatures up to 80°C without compromising magnetic efficiency

- Welded 3mm Stainless Steel housing to support symmetrical compression loads up to 4500kg

- Fully automated cleaning options with control package available

- Custom-made flanges to suit your application for easy installation

Description

FF Series Drawer Filter Magnets

- High Strength Neodymium Rare Earth Magnets with our unique temperature compensated design, for superior high temperature operation

- High Strength, fully welded 3mm Stainless Steel Body, capable of symmetrical compression loads of 4500kg.

- Patented “No Spill” Slide Gate, completely shuts off product flow for safe and clean removal of the drawer for cleaning.

- Flanges customised to customers own needs, for fast simple fitting.

- Range of optional extras, Standard Units Ex-Stock

- Designed to compliment the Bunting Magnetic MMS Metal Detector and can be supplied as turnkey cleaning station.

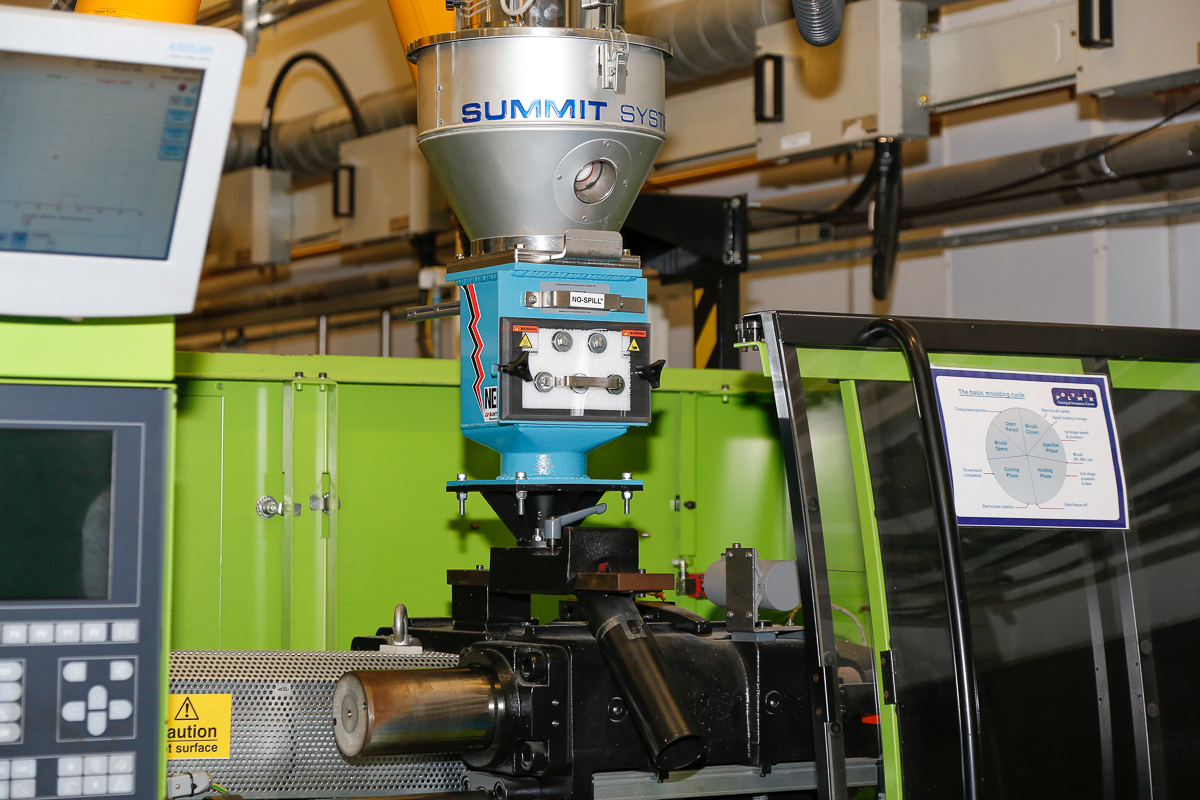

Bunting’s FF Series Drawer Magnets are perfectly suited for collecting and separating contaminant ferrous metal from gravity fed, dry, free flowing materials. Housed inside are the extremely strong Neodymium Rare Earth Magnets which do the capturing and holding of the tiny pieces of ferrous metal contaminant. Made specifically for the plastics industry, this is the only available drawer magnet design (exclusive to Bunting) that features temperature-compensated rare earth magnets. With that benefit on board, they are compatible with high temperature (up to 80°C) machines like extrusion, injection and blow moulding machines while still maintaining a maximum pulling power. Guaranteeing a level of durability and a reduction in downtime, this particularly impressive series of drawer magnets has been a leader in the industry for more than 40 years.

Featuring a 3mm stainless steel , fully welded , housing which has been built in order to support symmetrical compression loads of 4,536 KG. The draw gasket which is designed to resist heat aging and compression set is cut from Ethylene Propylene Diene (EPDM) and allows for greater durability.

Although entirely optional, the ability to order the FF Series Drawer Magnets with either a self-cleaning or continuously self-cleaning option means that any production downtime can be reduced significantly. A detachable tramp tray, which comes as part of the self-cleaning model, means that spillages and clean-ups can largely be avoided.

FF Series Options include:

Choose from either square or round spouting transition to make installation easier

- No-Spill Side Gate (1) – This effectively switches off the product flow. When the drawer is then removed for routine inspection or cleaning there are no concerns regarding health and safety or spillages.

- Purge Hopper (2) – This is put into use when changing colour or compound. It means the equipment can be cleaned without the need to empty the hopper. This will also mean that magnetics protection won’t be sacrificed.

- Dump Tube (3) – Designed to totally empty the draw housing and the material hopper once a plastic run has been completed.

- Liquid Port (4) – This port essentially has a dual purpose. It can hold a temperature probe but primarily it provides a means to inject liquid colour additive into resin.

- Powder Seal Kit (5) – Limits any leaking of powdery materials by putting a compression seal around the slide gate.

Applications

- Plastics Industry

- Injection Moulding

- Blow Moulding

- Plastics Extrusion

- Recycling Plastics

- Temperature compensated to sit directly above moulding machine

Videos