Recycling

Removing Metal Contamination from Recycling:

- Recovery or separation of ferrous metal – Larger ferrous metal is recovered using Permanent and Electro Overband Magnets, Electro Drum Magnets and Pulley Magnets. Smaller ferrous metals are separated using higher-intensity separators such as Permanent Drum Magnets;

- Separation of non-ferrous metals – The wide range of Eddy Current Separators enable optimum metal separation or maximum metal purity. Even very small non-ferrous particles are separated by the high-powered magnet rotor. For very fine particle separation, Bunting recommends the ElectroStatic Separator;

- Stainless steel and PCB recovery – Both materials are weakly magnetic and require the intense magnetic field of the patented HISC or SSSC high-intensity Magnetic Separator;

- Metal contaminated waste – Metal Detectors work alongside magnetic separators and finding and also removing all metals from non-metallic waste materials;

Technical Articles

Click below to see Bunting product applications in a typical recycling plant

Recycling Industry Products

Ferrous Metal Magnetic Separators

Stainless Steel Separators

Overband Magnets

Suspension Magnets

Drum Magnets - Electro

Recycling Industry Products

Ferrous Metal Magnetic Separators

Stainless Steel Separators

Ultra high-intensity magnetic separators to recover or remove weakly magnetic materials including fragmented stainless-steel and PCBs.

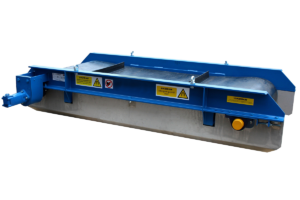

Overband Magnets

Overband magnets, suspended over conveyors, recover ferrous metal such as steel cans from conveyed waste and are available as permanent and electromagnetic designs.

Suspension Magnets

Suspension Magnets, suspended over conveyors, separate occasional ferrous metal and protect equipment such as shredders. Available in permanent and electromagnetic versions.

Drum Magnets - Electro

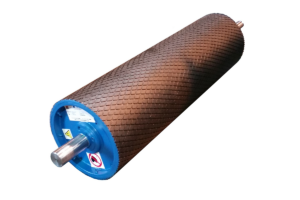

Magnetic Head Pulleys

The Magnetic Head Pulley replaces the standard head pulley of a conveyor to provide continuous separation of ferrous metals from conveyed products.

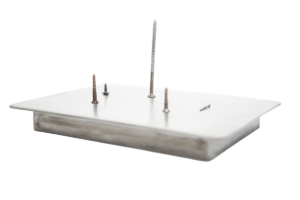

Plate Magnets

Permanent Plate Magnets, mounted in chutes and suspended above conveyors, to separate larger tramp metal.

Tube & Grid Magnets

High-strength Tube and Grid Magnets used to cleanse dry, free-flowing shredded or granulated waste of problematic ferrous metal contamination.

Magnetic Sweepers

Magnetic sweepers clear ferrous debris off floors, yards, car parks and other areas to prevent damage to equipment and vehicles.

Non-Ferrous Metal Separators

Eddy Current Separators

Recover and separate large and small non-ferrous metals from e-waste, household refuse, shredded auto scrap, plastic waste and other waste materials.

Electrostatic Separators

A new generation of metal separator, enabling the separation or recovery of fine non-ferrous metals such as copper wire and aluminium foil.

Metal Detectors

Free-Fall Metal Detectors

As dry, free-flowing plastic and shredded plastic waste falls through the metal detector, any identified tramp metal gets automatically rejected.

Conveyor Metal Detectors

High-sensitivity metal detectors mounted around a conveyor to locate any metal contaminant present in the transported waste.

Magnetic Head Pulleys

Plate Magnets

Tube & Grid Magnets

Magnetic Sweepers

Non-ferrous Metal Separators

Eddy Current Separators

Electrostatic Separators

Metal Detectors

Conveyor Metal Detectors

Metal Separators for Recycling

Metal separators are a vital stage for nearly all recycling processes. The range of technology, that includes magnetic separators, metal detectors, eddy current separators and electrostatic separators, enables both the recovery of valuable metals and the removal of metal contamination.

Magnetic Separators for Recycling

There is a long history of utilising magnetic separators to recover ferrous metals from non-magnetic materials such as household waste and auto-shredder metals. Traditional Electro Drum Magnets operate alongside ultra high-intensity Stainless Steel Separators to ensure the recovery and separation of all valuable ferrous metals.

Eddy Current Separators for Recycling

Eddy Current Separator technology changed the recycling landscape for non-ferrous metal recovery and separation. Bunting’s broad range of Eddy Current Separators enables recovery of both large and small non-ferrous metals in a diverse and ever-growing variety of recycling applications. ElectroStatic Separators compliment the range, providing final stage separation of fine non-ferrous metals such as copper wire.

Metal Detectors for Recycling

Metal Detectors are becoming increasingly important in the recycling industry. Magnetic Separators and Eddy Current Separators are widely used to remove liberated ferrous, non-ferrous and even some stainless-steel metals, but are unable to separate metals that are imbedded in material or are unresponsive to these types of metal separators. A common location for the Metal Detector is on the conveyor prior to size reduction, where it identifies the presence of any metal that may damage the shredder or granulator. The effect of metal damage can be costly in terms of repair and production downtime.